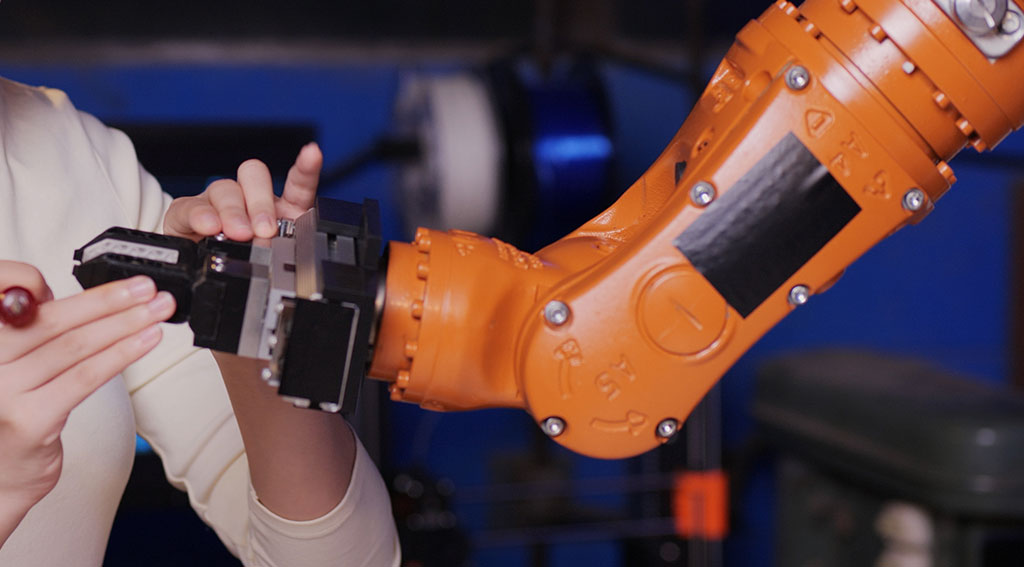

Industrial automation systems are an important tool that increase productivity by automating various processes. The equipment used in these systems requires periodic maintenance and service. These services improve the performance and extend the life of industrial automation equipment. Service and maintenance services include checking, repairing, and replacing mechanical and electronic components, as well as updating and configuring robot software. Service and maintenance should be done periodically to improve the performance of robots and extend their life. In addition, these services are also important to ensure that the systems operate properly.

RAS Industrial Automation provides professional support, service, maintenance, and consulting for the following brands in all areas of production.

- KUKA KRC1, KRC2, KRC4, KRC5

- ABB S3, S4, S4C, S4C+ ,IRC5

- Fanuc RJ2, RJ3, R30iA, R30iB

- Yaskawa XRC, NX100, DX100, DX200, YRC1000

- IGM RT330, K5

- Kawasaki

- NACHI

- OTC

- Hyundai

- Siemens PLC, PCS7

- Beckhoff TC2, TC3, NC, CNC

- Omron

- Schneider

- Mitsubishi

- APRIL

- Phoenix Contact

- Festo

- Siemens

- Sew

- Schneider

- Beckhoff

- Yaskawa

- Lenze

- Kollmogren

- ARO

- Bosch

- Nimak

- OBARA

- Fronius

- Kemppi

- Abicor Binzel

- Dinse

- EWM

- Merkle

- Cognex

- Keyence

- SICK

- Basler

- Teledyne Dalsa Scherlock

- Halcon

- National Instruments Vision AI

- SIC Marking

- Telesis

- Keyence

- Borries

- Perceptron Robotik CMM

- Trumpf, ROFIN, Bystronic, IPG Laser generators

- ATEQ Leak and Pressure Test Equipment

- MARPOSS Measuring Instruments

- HIGHYAG Remote Laser Solutions

- Desoutter

- Atlas Copco

- Stanley