RAS Automation – OPC UA Technology Suite for KUKA Robots

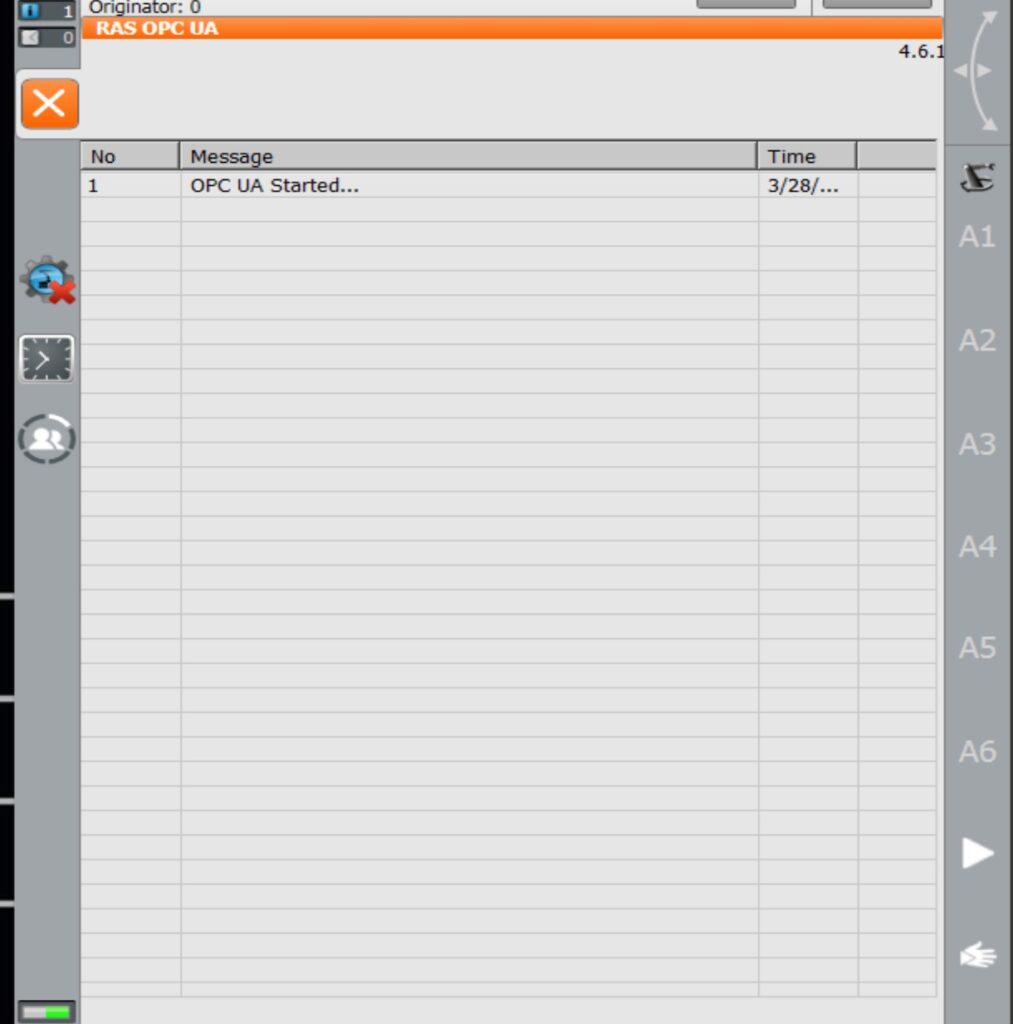

The KUKA OPC UA Technology Suite developed by RAS Automation provides standardised, secure and flexible communication between KUKA robots and industrial systems. Thanks to the OPC UA protocol, we offer full compliance with Industry 4.0 and Smart Factory applications by facilitating the integration of robots with SCADA, HMI, MES, ERP and other automation systems. The add-on package creates an OPC UA Server platform that is fully integrated on the robot and does not require complex installation. The user can easily configure the variables to be shared and open them to remote systems.

General Features

- OPC UA Compatibility: Provides secure and uninterrupted data exchange with all supported client devices with the OPC UA standard.

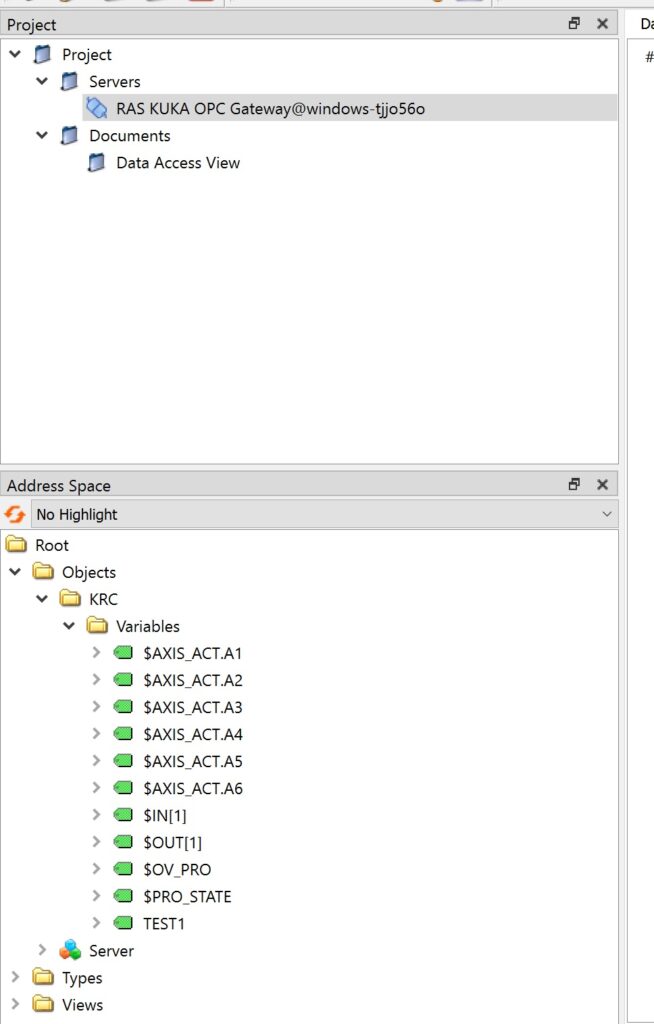

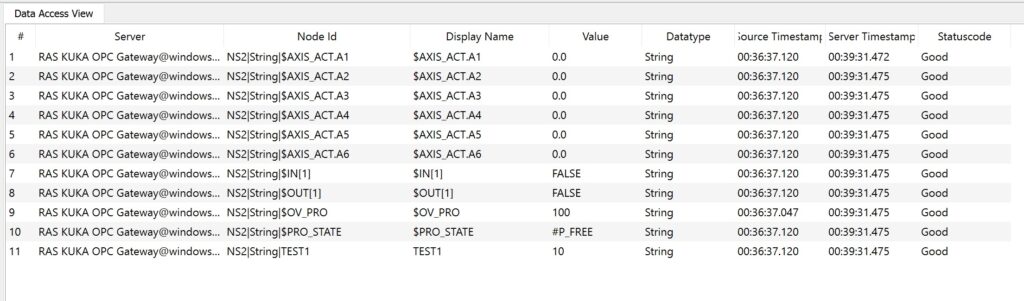

- Real-time Data Sharing: KUKA robots’ movements, instant position information, signal data and error codes can be monitored in real time. In addition, user-defined variables can be easily added to the system.

- Bidirectional Communication: OPC UA clients can send commands to robots and control processes. At the same time, real-time values can be given to robot variables from remote systems.

- Advanced Security: Data security is ensured with security measures such as encryption, authentication and user authorisation offered by OPC UA.

- Flexible Data Configuration: User-specific OPC UA nodes can be created and all data related to the robot can be configured.

- Easy Integration to Automation Software: It offers full compatibility with popular software such as Siemens WinCC, Ignition, Wonderware, Kepware, LabVIEW, Codesys. Compatible with all clients that support OPC UA.

- High Performance & Low Latency: Provides minimum latency with optimised data transfer protocols.

Technical Specifications

| Features | Description |

| Supported KUKA Control Systems | KRC4, KRC5 System software KSS 8.5.7 and above |

| OPC UA Version Support | OPC UA 1.03 and above |

| Connection Types | Communication via TCP/IP, Ethernet KLI or KONI port. |

| Data Transfer Rate | Real-time (delay as low as 50ms) |

| Authentication | User, role-based access control |

| Encryption | AES-256, RSA, X.509 certificates |

| Supported OPC UA Clients | SCADA, HMI, PLC, ERP, MES, IIoT platforms or other clients supporting OPC UA |

Areas of Use

- Smart Factories: Optimises production processes by synchronising production lines with robots.

- Automotive Industry: It offers the opportunity to monitor and control robot movements on assembly lines.

- Food and Pharmaceutical Industry: Provides quality control by tracking sensitive data in production processes.

- Logistics and Warehousing: It can be used in warehouse management with autonomous robot systems.

- Education and Research: It allows remote control and monitoring of industrial robots for universities and R&D centres.

Why the KUKA OPC UA Technology Pack?

- Customised Solutions: We can develop special OPC UA data models for your projects.

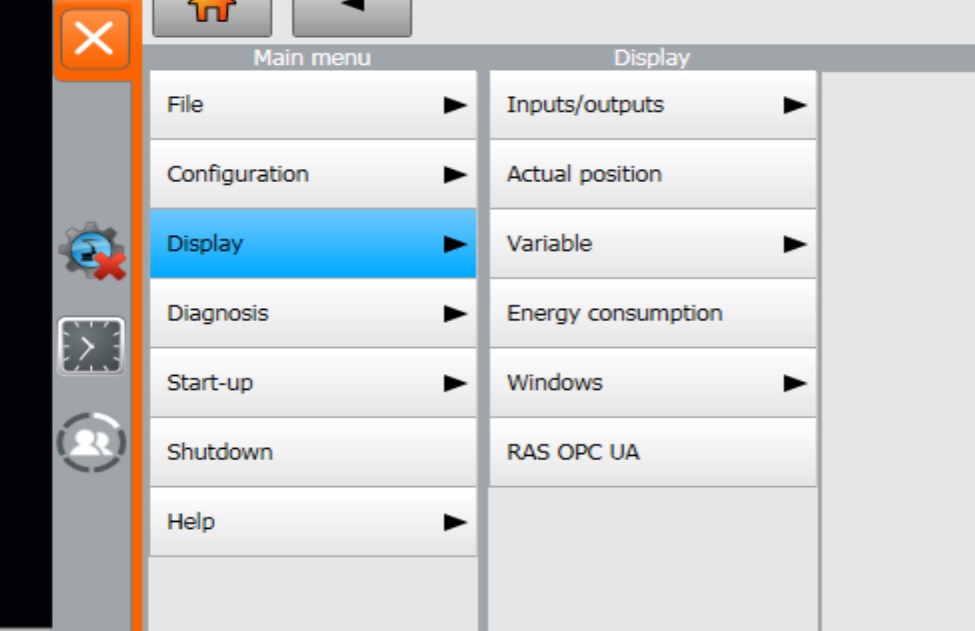

- Easy Installation: Thanks to its simple interface, you can configure it quickly.

- High Security: It provides maximum data protection with the latest security measures offered by OPC UA.

- Industry 4.0 Compatible: Increases productivity by accelerating the digital transformation of your factory.

- Cost-effective

Contact us for more information!

Contact us to add OPC UA-based connectivity to your KUKA robots or to develop customised solutions.