Automation panel manufacturing refers to the production process of electric panels used in many different industrial applications. These panels consist of a variety of components and are typically used to control and operate automated systems. For example, in a manufacturing facility, an industrial panel can control the production of a product by moving machine parts. Similarly, in an energy production facility, an automation panel can control the movement of a wind turbine to control energy production.

Industrial panel manufacturing typically involves the design, production, and installation of electric panels consisting of a variety of components.

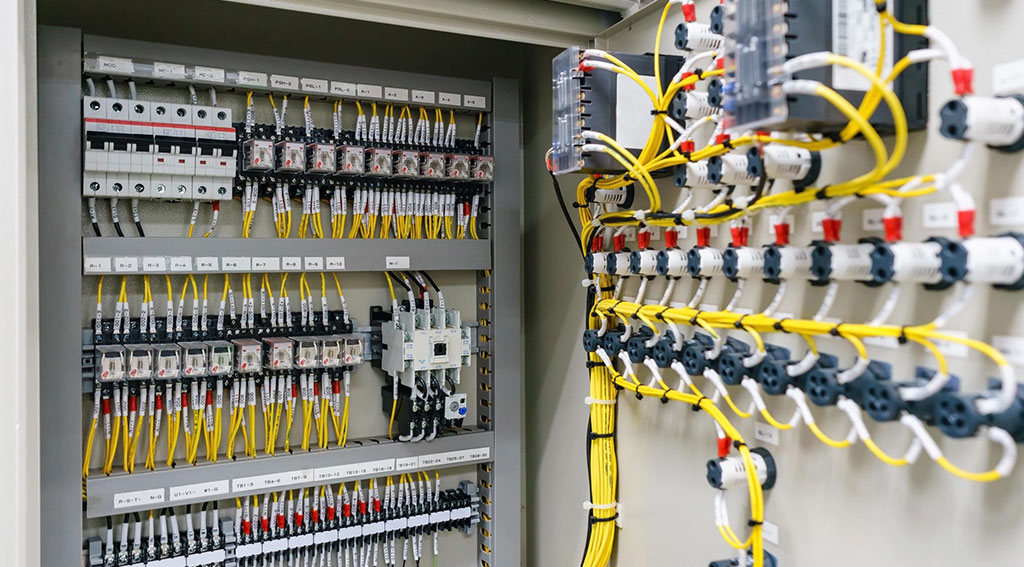

The automation panel production process begins with the design of electrical circuits. These circuits are designed to enable the operation of the automation panel and drawings are made. Next, the required cable wiring is carried out for the automation panel. This wiring carries the energy required for the electrical circuits to operate and connects electric equipment with each other. Then, the required electric equipment for the automation panel is connected to the cable wiring and assembled. These equipment include components such as control units, motion drives, and moving parts. The automation panel production process ends with the testing of the automation panel. These tests are carried out to check the operation and safety of the panel and necessary corrections are made.

Once these steps are completed, the automation panel production process is complete and the panel is ready to be used in the industrial application where it is installed. Automation panel production is typically carried out using a variety of equipment and technology.